Every day, industrial workers face potential hazards that could lead to serious injuries or fatalities if not properly identified and controlled.

According to the Association of Workers’ Compensation Boards of Canada (AWCBC), 993 workplace fatalities were recorded in Canada in 2023. Many of these incidents could have been prevented with thorough risk assessment and proper hazard control measures.

From toxic gas exposure on drilling sites to falls from scaffolding on construction sites, these dangers are part of everyday operations. Risk assessments provide a systematic approach to identifying hazards before incidents occur. By conducting thorough assessments, you can implement controls that protect lives, prevent costly downtime, and maintain operational efficiency.

In this article, we’ll break down the risk assessment process step-by-step and provide practical examples specific to oil and gas, construction, mining, forestry, and pulp and paper industries. You’ll learn how to identify hazards, evaluate risks, and implement effective controls that keep your workplace safe.

How can risks be assessed?

Assessing risks involves evaluating two key factors: the likelihood of a hazard causing harm and the severity of the consequences if that harm were to occur. Unlike hazard identification, which simply involves recognizing potential sources of danger, risk assessment takes it a step further by analyzing the probability of an incident and the possible severity of its impact.

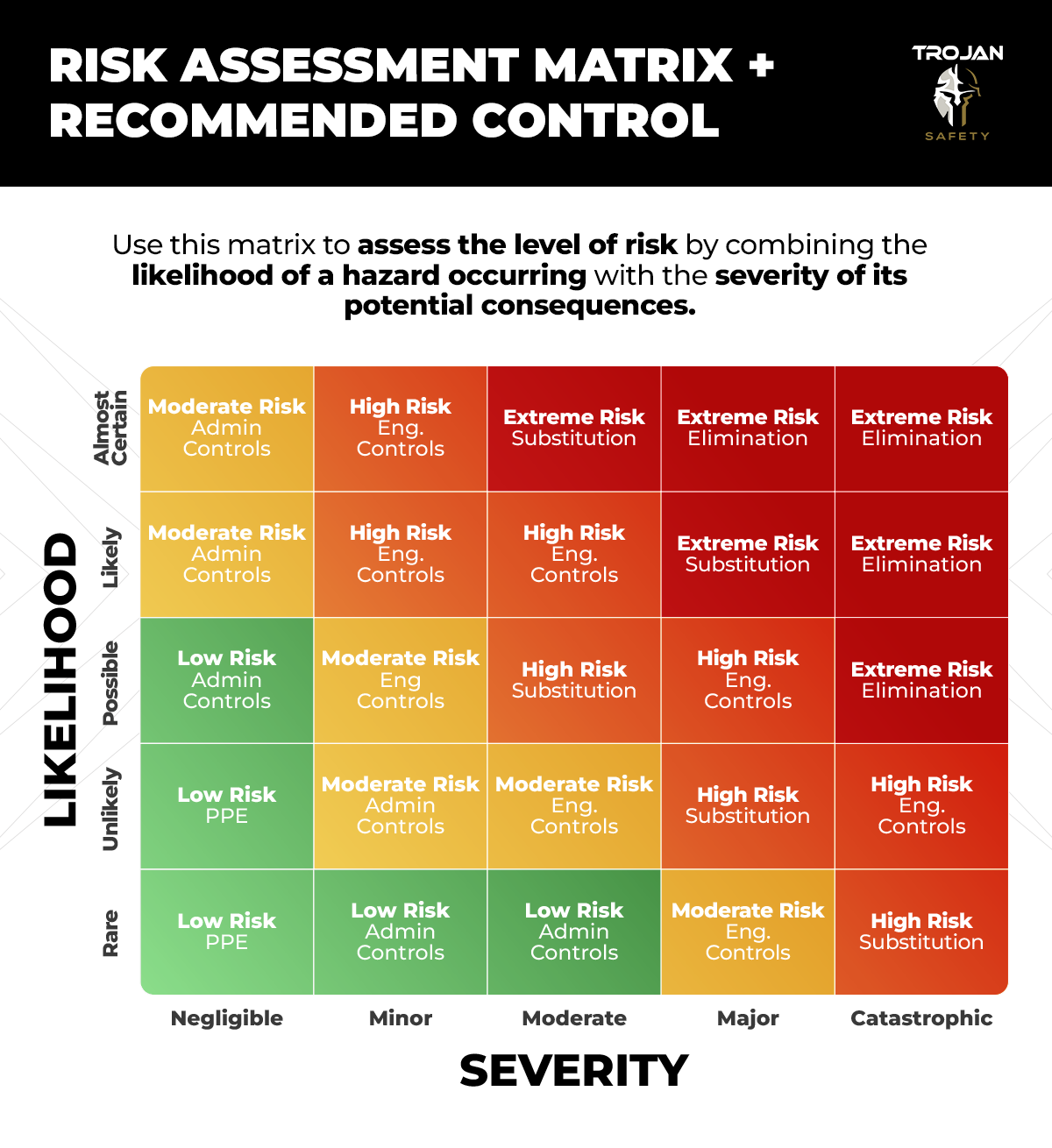

To standardize risk assessment, most industrial workplaces use a risk assessment matrix. This tool provides a consistent framework for measuring and comparing various risks.

Understanding the Risk Assessment Matrix

A risk assessment matrix is a visual tool that helps workers and safety managers evaluate risks by plotting likelihood against severity. This approach ensures consistency across different teams, shifts, and job sites.

The foundation of any risk assessment is understanding this basic formula:

Risk = Likelihood × Severity

This means that even a hazard with severe consequences may be considered lower risk if the likelihood of its occurrence is extremely low. Conversely, a hazard with moderate consequences but high likelihood may require immediate attention and control measures.

The matrix typically uses a colour-coded system to indicate risk levels, making it easy to identify which hazards require immediate attention and which can be managed with standard controls. By using a matrix, organizations can prioritize safety resources effectively and ensure that the most critical risks are addressed first.

Likelihood

Likelihood refers to the probability that a hazard will actually cause harm. In most risk assessment tools, likelihood is categorized into five levels:

- Rare: The incident may occur only in exceptional circumstances. An example would be a catastrophic failure of a recently inspected and certified pressure vessel.

- Unlikely: The incident could occur, but is not expected under normal circumstances. For example, a properly maintained and inspected scaffold is unlikely to collapse.

- Possible: The incident might occur at some point. An example would be equipment malfunction due to wear and tear if regular maintenance schedules are followed, but components eventually fail.

- Likely: The incident will probably occur under most circumstances. For instance, workers handling chemicals without proper PPE will likely experience skin irritation or exposure.

- Almost Certain: The incident is expected to occur in most circumstances. For example, workers entering a confined space without proper ventilation will almost certainly be exposed to oxygen deficiency or toxic gases.

Severity

Severity measures the potential consequences if a hazard does cause harm. Like likelihood, severity is typically divided into five categories:

- Negligible: No injury or extremely minor injury requiring no treatment, property damage, or operational impact. An example would be a small splinter or minor skin irritation that resolves on its own.

- Minor: Injury requiring only first aid treatment, minimal property damage, or brief operational interruption. This might include minor cuts, bruises, or eye irritation.

- Moderate: Injury requiring medical treatment beyond first aid, moderate property damage, or temporary operational delays. Examples include lacerations requiring stitches or minor chemical burns.

- Major: Serious injury requiring hospitalization, significant property damage, or extended operational disruption. This could include adverse health effects such as fractures, severe burns, or amputation of fingers.

- Catastrophic: Death or permanent disability, extensive property damage, or complete operational shutdown. Examples include fatalities from H2S exposure or a major explosion at an oil and gas facility.

Step-by-Step Risk Assessment Procedure

Conducting an effective risk assessment requires a systematic approach that ensures all hazards are identified and properly evaluated. By following these steps, you can create a thorough evaluation that protects workers and maintains operational safety.

Step 1: Identify the Hazard

The first step in any risk assessment is recognizing what could cause harm in your workplace. This involves conducting thorough workplace inspections, reviewing incident reports, and consulting with workers who perform these tasks daily.

Ask yourself questions such as:

- What substances or environments do workers interact with?

- What equipment could cause injury if it malfunctions or is misused?

- What heights or elevated platforms are present?

- What could cause workers to slip, trip, or fall?

- Where might workers strain themselves or experience ergonomic issues?

Review Material Safety Data Sheets (MSDS) for chemical hazards, inspect equipment for wear and tear, and monitor air quality for gas concentrations. Involve experienced workers in this process, as they often have valuable insights into hazards that may not be immediately obvious.

Step 2: Evaluate the Risk

Once hazards are identified, evaluate the risk using the risk assessment matrix. Assign a likelihood and a severity rating to each hazard. Plot these on the matrix to determine the overall risk level.

For example:

- “Likely” likelihood + “Major” severity = “High Risk” or “Extreme Risk”

- “Unlikely” likelihood + “Minor” severity = “Low Risk”

Next, consider who could be affected, including workers performing the task, supervisors, contractors, visitors, and employees in nearby areas. Different groups may face different risk levels based on experience, health conditions, or proximity to the hazard.

Step 3: Record Your Findings

Record keeping is a critical component of risk assessment. Record all identified hazards, the risk ratings assigned, and the reasoning behind those ratings. This creates a reference point for future assessments and demonstrates due diligence in meeting safety regulations.

Your documentation should include:

- Date of the assessment

- Personnel involved in the assessment

- Description of each hazard

- Likelihood and severity ratings

- Overall risk level

- Current control measures are in place

- Additional controls required

Ensure these records are accessible to workers, supervisors, and safety managers. Review and update them regularly to keep the assessment relevant as conditions change.

Step 4: Implement Control Measures

After analyzing risks, implement control measures following the hierarchy of controls. This hierarchy prioritizes the most effective methods for reducing risk:

- Elimination: Remove the hazard entirely

- Substitution: Replace the hazard with something less dangerous

- Engineering Controls: Isolate people from the hazard using physical barriers or systems

- Administrative Controls: Change work practices and procedures

- Personal Protective Equipment (PPE): Protect workers with safety gear

For high-risk and extreme-risk hazards, prioritize elimination and substitution whenever possible. Administrative controls and PPE may be sufficient for lower-level risks.

Step 5: Review and Update Regularly

Risk assessments are not one-time activities. Workplace conditions, equipment, processes, and personnel change over time, which means new hazards may emerge and existing controls may become less effective.

Schedule regular reviews of your risk assessments, particularly when:

- New equipment or processes are introduced

- An incident or near-miss occurs

- Workers report new concerns

- There are changes to regulations or industry standards

- Significant time has passed since the last assessment (at a minimum, annually)

Continuous monitoring and updating ensure that your risk assessment remains an effective tool for maintaining a safe workplace.

Examples of a Risk Assessment in Industrial Workplaces

Understanding risk assessment theory is important, but seeing how it applies to real-world scenarios helps bring the concepts to life. Below are practical examples of risk assessments across different industrial sectors.

Oil and Gas

Scenario: H2S Exposure During Well Servicing

Hazard: Hydrogen sulphide (H2S) gas release during well maintenance operations at a sour gas well site.

H2S is commonly present in sour gas wells and can be released during maintenance activities. Exposure can cause loss of consciousness within seconds and death within minutes at high concentrations.

Who Could Be Harmed: Well servicing crew members, site supervisors, equipment operators, and workers in nearby areas.

Risk Evaluation: Likely likelihood + catastrophic severity = extreme risk

Control Measures:

- Install continuous H2S gas detection systems with alarms positioned at ground level and automated shutdown systems

- Establish exclusion zones with restricted access and conduct mandatory pre-job safety meetings

- Require H2S Alive certification for all personnel and provide SCBA equipment and personal H2S monitors

- Station-trained H2S safety specialists on-site with rescue equipment

Construction

Scenario: Trench Collapse During Excavation Work

Hazard: Soil collapse in a trench 3 metres deep, being excavated for underground utility installation.

Trenches can collapse due to soil type, moisture content, weather conditions, or nearby traffic vibrations. Workers can be buried alive, leading to suffocation or crush injuries.

Who Could Be Harmed: Workers inside the trench, equipment operators near the trench edge, and labourers moving materials.

Risk Evaluation: Possible likelihood + catastrophic severity = extreme Risk

Control Measures:

- Install proper trench shoring systems or use hydraulic shores and trench boxes for structural support

- Designate someone to conduct daily inspections before worker entry and after any weather events

- Keep heavy equipment and excavated soil at least 1 metre back from the edge, and position ladders every 7.5 metres

- Where possible, use trenchless technology to avoid excavation entirely

Mining

Scenario: Silica Dust Exposure During Drilling Operations

Hazard: Inhalation of respirable crystalline silica dust during drilling and blasting in an underground mine.

Silica dust is generated in most mining operations. While prolonged exposure can lead to silicosis and respiratory diseases over time, immediate effects are less severe than acute hazards.

Who Could Be Harmed: Drill operators, blasters, equipment operators, and workers in poorly ventilated areas.

Risk Evaluation: Likely likelihood + moderate severity = moderate risk

Control Measures:

- Install ventilation systems and use water suppression during drilling to minimize airborne dust

- Conduct regular air quality monitoring and limit worker exposure time in high-dust areas

- Provide respirators rated for silica dust with proper fit testing and training

- Implement regular health monitoring, including pulmonary function tests, for exposed workers

Forestry and Pulp & Paper

Scenario: Chainsaw Kickback in Forestry Operations

Hazard: Chainsaw kickback causing lacerations or cuts during tree felling and bucking operations.

With proper training, well-maintained equipment with safety features, and correct operating techniques, kickback incidents are uncommon. When they occur, injuries typically require medical treatment beyond first aid, such as stitches for lacerations.

Who Could Be Harmed: Fallers, buckers, forestry workers, and nearby crew members.

Risk Evaluation: Unlikely likelihood + moderate severity = low to moderate Risk

Control Measures:

- Use chainsaws equipped with chain brakes, anti-kickback chains, and reduced kickback guide bars

- Provide comprehensive chainsaw safety training and ensure all operators are certified

- Establish clear work zones with minimum distances between workers and implement communication protocols

- Require chainsaw chaps, steel-toed boots with cut protection, hard hats with face shields, and hearing protection

Equip Your Workplace with Proper Risk Assessment Training

Understanding how to conduct risk assessments is a critical skill that can prevent incidents before they happen.

Without proper training, even well-intentioned risk assessments can miss critical hazards, underestimate risks, or implement inadequate controls. This leaves your workplace vulnerable to incidents that could have been prevented.

At Trojan Safety, we specialize in providing industrial safety training that addresses the real-world challenges workers face in oil and gas, construction, mining, forestry, and pulp and paper industries. Our programs prepare your team to identify hazards and manage risks effectively.

Our comprehensive safety training programs include:

- Confined Space Entry & Rescue

- H2S Alive

- Ground Disturbance

- Fall Protection

- First Aid (Basic, Intermediate, Advanced)

- Detection and Control of Flammable Substances

- Oilfield Driver Awareness

- Transportation Endorsement

Contact us today to learn how we can enhance the safety of your industrial operations through expert training and on-site safety services.

Written By: Jeff Kirschner, General Manager

Written By: Jeff Kirschner, General Manager