Chemical hazards are among the most serious workplace safety risks, yet they often go unnoticed until it’s too late.

Unlike physical hazards that workers can see and avoid, chemical dangers can be invisible and odourless and cause both immediate and long-term health effects. Industries like oil and gas, mining, and construction face particularly high risks due to the nature of their operations and the substances they handle.

This comprehensive guide will help you understand hazardous chemicals, identify the types most commonly found in industrial workplaces, and implement effective control measures to protect your employees and operations.

What is a Chemical Hazard?

A chemical hazard is any substance that can cause adverse health effects when workers are exposed to it, or property damage and environmental harm when released or improperly handled. These hazards exist in various forms, such as gases, liquids, solids, vapours, fumes, and dusts, and can enter the body through inhalation, skin contact, ingestion, or absorption.

Unlike other workplace hazards, chemical hazards are dangerous because their effects aren’t always immediate or obvious. While a fall from a height causes instant injury, chemical exposure might take years to show up as cancer, lung disease, or neurological damage. This delayed response makes chemical hazards particularly dangerous, as workers may continue unsafe practices without realizing the building harm.

In industrial environments, chemical hazards are often byproducts of necessary processes rather than intentionally used substances. For example, welding produces toxic fumes, diesel engines emit harmful exhaust, and cleaning solvents release vapours that can cause serious health issues over time.

These substances can naturally occur, like hydrogen sulphide gas found in oil and gas operations, or be manufactured, such as industrial solvents and cleaning agents. Regardless of their origin, all chemical hazards require careful identification, assessment, and control to prevent worker injury and illness.

Types of Chemical Hazards in the Workplace

Chemical hazards are classified into various categories based on how they affect a person’s health. Each type requires different safety precautions and control measures.

Asphyxiants

Asphyxiants are substances that prevent your body from getting enough oxygen. Simple asphyxiants displace oxygen in the air, while chemical asphyxiants stop your body from using oxygen properly.

Examples include:

- Hydrogen sulphide (H2S) from oil and gas operations or wastewater treatment

- Carbon monoxide (CO) from engines, generators, or combustion processes

- Methane from landfills, sewers, or drilling operations

Prevention tips: Use continuous gas monitoring in confined spaces and areas where these gases may be present. Ensure proper ventilation systems are installed and working before starting work.

Corrosives

Corrosives destroy or damage living tissue and materials through chemical action. They can cause severe burns to the skin, eyes, and respiratory system and damage equipment and structures.

Examples include:

- Sulfuric acid, which is used in battery manufacturing or metal processing

- Hydrochloric acid for cleaning or etching metals

- Sodium hydroxide (caustic soda) in pulp and paper production

Prevention tips: Provide chemical-resistant gloves, eye protection, and protective clothing. Install emergency eyewash stations and safety showers near work areas.

Irritants

Irritants cause inflammation or irritation to the skin, eyes, nose, throat, or lungs upon contact. While not usually life-threatening, they can cause significant discomfort and, with repeated exposure, lead to more serious health problems, such as chronic bronchitis or dermatitis.

Examples include:

- Chlorine gas from water treatment or bleaching processes

- Solvents like acetone or toluene from painting or degreasing

- Sawdust and wood particles from forestry operations

Prevention tips: Use local exhaust ventilation to capture fumes and particles at the source. Rotate workers to limit exposure time to irritating substances.

Sensitizers

Sensitizers cause allergic reactions that get worse with each exposure. Once someone becomes sensitized, even tiny amounts can trigger severe reactions, making continued work exposure dangerous.

Examples include:

- Isocyanates from spray painting or foam manufacturing

- Epoxy resins that are used in coatings and adhesives

- Certain wood dusts from forestry and woodworking

Prevention tips: Train workers to recognize early signs of allergic reactions. When possible, use enclosed systems or remote handling methods to minimize contact.

Teratogens

Teratogens are substances that can cause birth defects or harm to developing babies when pregnant workers are exposed. These chemicals are hazardous because they can affect pregnancy even at low exposure levels, though many teratogens also pose health risks to all workers.

Examples include:

- Lead from old paint, plumbing, or battery operations

- Mercury from mining operations or specific industrial processes

- Certain organic solvents that are used in manufacturing processes

Prevention tips: Reassign pregnant workers away from areas with known teratogens. Minimize exposure for all workers through proper ventilation and strict hygiene practices to prevent take-home contamination.

Mutagens

Mutagens damage genetic material (DNA) in cells, leading to health issues like cancer. These substances can affect both your current workers and potentially their future children.

Examples include:

- Benzene from petroleum refining or chemical manufacturing

- Welding fumes, primarily from stainless steel

- Vinyl chloride from plastics manufacturing

Prevention tips: Use proper ventilation and fume extraction during welding operations. Store and handle these materials in designated areas with restricted access.

Carcinogens

Carcinogens are substances that cause cancer. These chemicals are among the most dangerous because cancer may not develop until years or decades after exposure, making early detection and prevention critical.

Examples include:

- Asbestos from older building materials or insulation

- Silica dust from sandblasting, concrete cutting, or mining

- Diesel exhaust from heavy equipment and vehicles

Prevention tips: Have materials tested for asbestos before demolition or renovation work. Use water suppression systems when cutting concrete or other silica-containing materials. Maintain and service diesel equipment regularly to reduce harmful emissions.

Reactive

Reactive chemicals can explode, catch fire, or release toxic gases when they come into contact with air, water, or other substances. They’re unpredictable and can cause sudden, catastrophic incidents.

Examples include:

- Acetylene gas, which is used in welding and cutting operations

- Hydrogen peroxide at high concentrations

- Compressed gases that can rupture containers explosively

Prevention tips: Store reactive chemicals away from incompatible materials and ignition sources. Inspect storage containers and connections regularly for leaks or damage.

Flammable

Flammable substances easily catch fire and burn rapidly, creating fire and explosion hazards. They’re particularly dangerous in enclosed spaces or areas with ignition sources.

Examples include:

- Gasoline and diesel fuel that are used in vehicles and equipment

- Propane for heating, welding, and forklifts

- Paint thinners and solvents

Prevention tips: Eliminate ignition sources like sparks, hot surfaces, and open flames in storage areas. Use proper grounding and bonding when transferring flammable liquids.

Health Conditions Caused by Chemical Hazards

Chemical exposure can cause a wide range of health problems, from immediate injuries requiring emergency treatment to long-term diseases that develop over time. Understanding these health effects helps you recognize when workers are exposed and ensures they receive proper medical care.

Immediate Health Effects

These health problems show up right away or within hours of exposure. They require immediate medical attention and often indicate a serious exposure incident that needs investigation.

Respiratory problems are among the most common immediate effects. Workers may experience coughing, shortness of breath, throat irritation, or difficulty breathing after inhaling toxic fumes, gases, or particles. In severe cases, chemical exposure can cause fluid buildup in the lungs, which can be life-threatening.

Chemical burns occur when corrosive substances contact the skin or eyes. These burns can be more serious than heat burns because the chemical continues to damage tissue until it is completely removed. Even brief contact with strong acids or bases can cause permanent scarring or blindness.

Poison symptoms can develop quickly with exposure to certain chemicals. Workers may experience dizziness, nausea, vomiting, confusion, or loss of consciousness. Hydrogen sulphide exposure, common in oil and gas operations, can cause workers to collapse within minutes at high concentrations.

Allergic reactions from sensitizing chemicals can range from skin rashes to severe breathing problems. Once a worker becomes sensitized, even small amounts of the chemical can trigger increasingly severe reactions.

Long-Term Health Effects

These health conditions develop slowly over months or years of repeated exposure. They’re often more serious because the damage builds up before symptoms appear, making prevention crucial.

Cancer is one of the most serious long-term effects of chemical exposure. Substances like asbestos, silica dust, and certain welding fumes increase cancer risk. Lung cancer is the most common, but chemical exposure can also cause cancers of the bladder, kidney, and other organs.

Respiratory diseases develop from long-term exposure to dusts, fumes, and vapours. Silicosis from concrete and stone cutting, asbestosis from older building materials, and chronic bronchitis from various industrial processes can permanently reduce lung function and quality of life.

Neurological damage affects the brain and nervous system. Long-term exposure to solvents, heavy metals like lead and mercury, and certain gases can cause memory problems, difficulty concentrating, tremors, and loss of coordination. These effects often worsen over time, even after exposure stops.

Reproductive health problems can affect both men and women exposed to certain chemicals. Some substances can reduce fertility, cause miscarriages, or lead to birth defects in children of exposed workers.

The serious nature of these health effects shows why preventing chemical exposure is so important. Once health damage occurs, it’s often permanent and can affect workers for the rest of their lives.

How to Control Hazardous Substances on Your Worksite

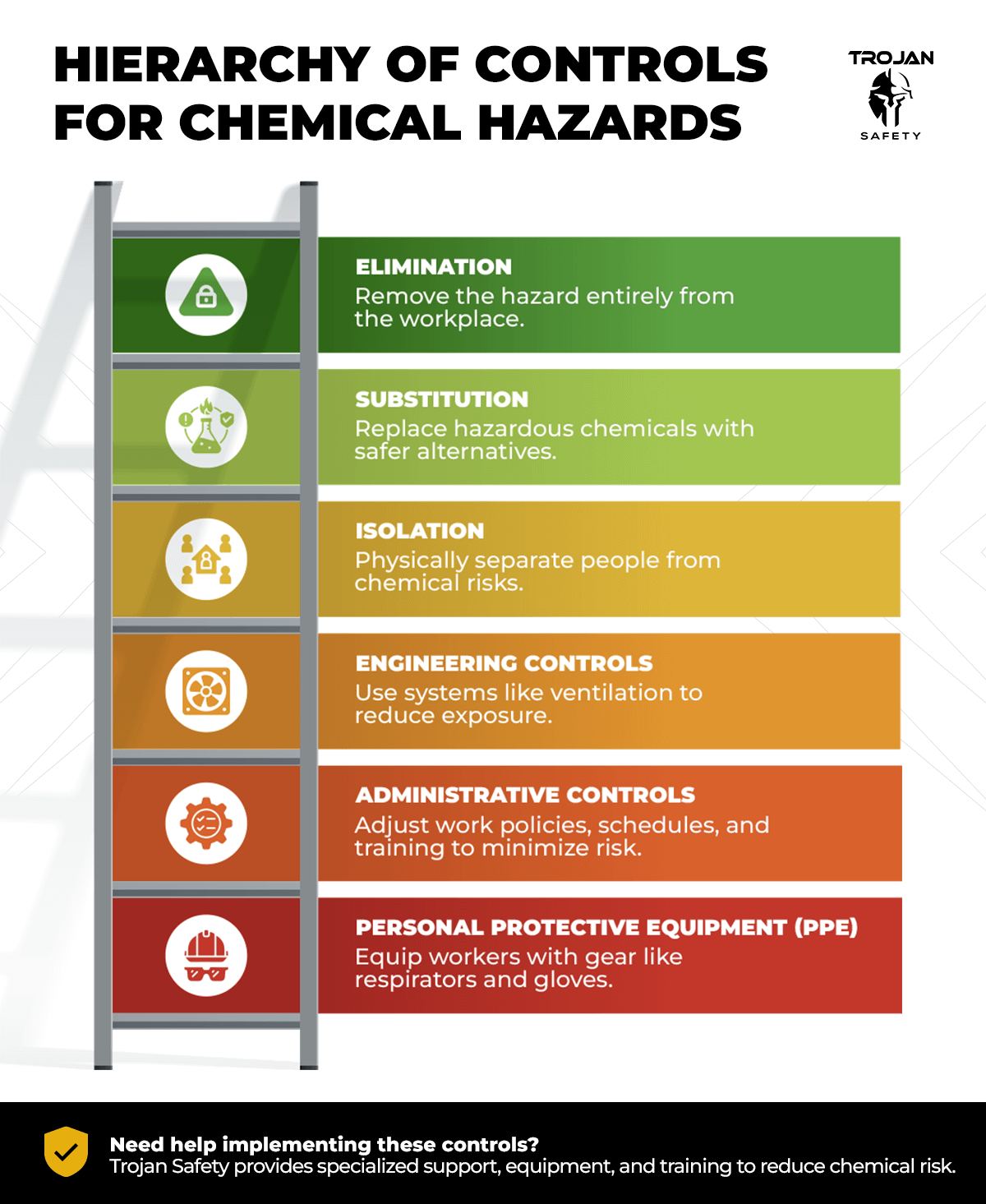

Protecting workers from chemical hazards requires a systematic approach that addresses exposures at their source rather than relying solely on protective equipment. The most effective strategy follows the control hierarchy, prioritizing the most reliable protection methods.

Implement the Hierarchy of Controls

Elimination

Elimination completely removes the chemical hazard from your workplace. This is the most effective control because if the toxic substance isn’t there, your workers can’t be exposed to it.

For example, switching from solvent-based paints to water-based alternatives eliminates toxic vapour exposure, or using mechanical cleaning methods instead of chemical degreasers removes the need for dangerous substances entirely.

While elimination provides the best protection, it’s not always possible in industrial operations, making substitution the next best option.

Substitution

Substitution replaces dangerous chemicals with safer alternatives that can do the same job. While not as effective as elimination, it can significantly reduce the risk placed on your team.

Common examples include using less toxic solvents for parts cleaning or switching to water-based cutting fluids instead of oil-based products.

Make sure any replacement actually reduces risk; some “safer” alternatives may have their own hazards or require workers to use more product to get the same results.

Isolation

Isolation physically separates workers from chemical hazards using barriers, distance, or time restrictions. This approach keeps dangerous processes away from most workers while allowing necessary operations to continue.

Creating designated areas for chemical storage with restricted access or using remote-controlled equipment for dangerous operations are effective ways to protect workers.

Isolation works best when combined with other controls and proper training, as workers still need protection when entering isolated areas.

Engineering Controls

Engineering controls use mechanical systems to remove or reduce chemical hazards at their source. These systems work automatically and don’t depend on workers remembering to use them properly.

The most common examples are local exhaust ventilation, which captures fumes right where they’re produced, and general ventilation systems, which dilute airborne contaminants.

Well-designed engineering controls can dramatically reduce chemical exposures, but regular maintenance is needed to ensure the controls continue to work effectively.

Administrative Controls

Administrative controls change how work is done to reduce chemical exposures through policies, procedures, training, and work practices.

Specialized training courses, such as H2S Alive and Detection and Control of Flammable Substances, can help workers understand and manage specific chemical risks in their workplace.

These controls are essential for maintaining awareness and safe practices, though they work best when combined with engineering controls for complete protection.

Personal Protective Equipment

Personal protective equipment (PPE) is your final protection against chemical hazards. While essential for complete protection, it should never be the only control method because it’s the least reliable approach.

Respirators and chemical-resistant gloves are the most common forms, but PPE only protects the person wearing it and fails if it’s not properly selected, fitted, maintained, or used.

The best results come from using multiple control methods together. This layered approach ensures that even if one control fails, other controls are still in place to protect workers.

Conduct Chemical Safety Audits

Regular safety audits help you identify chemical hazards, assess your current controls, and identify areas for improvement. These systematic reviews ensure your chemical safety program works as your site evolves.

Start by reviewing all chemicals used or produced at your site, including cleaning supplies and process byproducts like welding fumes. Pay special attention to areas where chemicals are mixed, transferred, or heated, as these create the highest exposures. Check that ventilation systems are working correctly and emergency equipment like eyewash stations are accessible and functional.

Document your findings and create action plans with specific deadlines and responsible parties.

It’s important to conduct formal audits at least annually, with more frequent reviews in high-risk areas or after significant process changes.

Partner With Trojan Safety to Control Chemical Hazards on Your Site

Controlling chemical hazards takes the right combination of training, equipment, and response capabilities. With over 30 years of experience in Western Canada’s industrial sectors, we understand the specific chemical risks your operations face.

We can help you manage chemical hazards through:

- H2S safety services and emergency response for oil and gas operations

- Air quality monitoring with real-time gas detection equipment

- H2S Alive and Detection and Control of Flammable Substances training courses

- Medical and paramedic services for chemical exposure incidents

- Decontamination and fire services for chemical spills and emergencies

From training your crew to emergency response services, we have the tools and experience to help you manage chemical risks effectively.

Contact us today to discuss your chemical safety needs.

Written By: Jeff Kirschner, General Manager

Written By: Jeff Kirschner, General Manager